CE, SIL-3 & ATEX Certifications

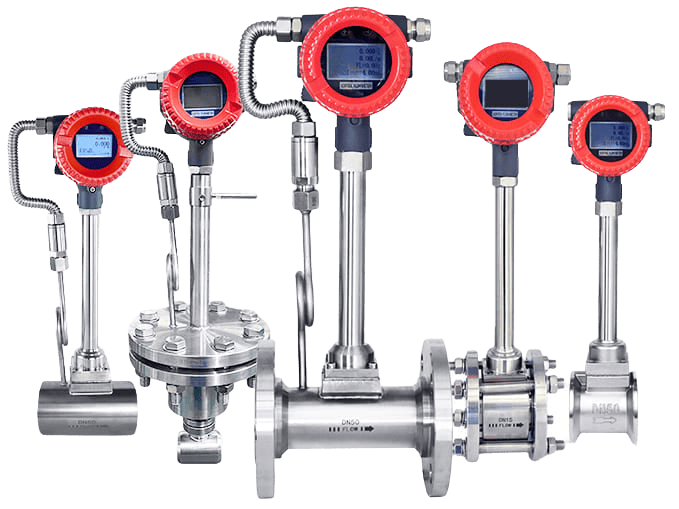

vortex Flow Meters

Designed for sectors where operational stability and low maintenance are critical.

Our vortex flowmeters are developed to maintain signal stability and measurement integrity across a wide range of industrial operating conditions. Built on calibrated bluff-body geometry, high-temperature–resistant materials, and advanced signal extraction techniques, our vortex portfolio provides dependable performance where energy measurement, utility control, and process monitoring demand consistency.

Request Your Free Quote Now

Flawless Flow Monitoring Starts Here

Vortex Metering Solutions for All Industrial Conditions

Our vortex flowmeters includes a structured selection of meter types engineered to fit varying installation constraints, process conditions, and utility measurement requirements.

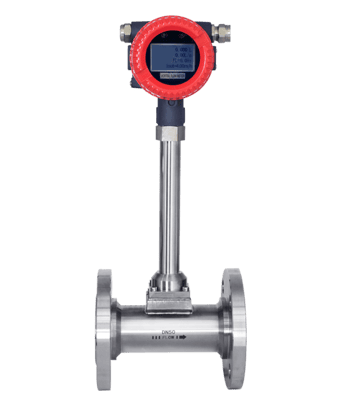

Flange Vortex Flowmeter

Design for process pipelines in chemical, energy, and general industrial systems.

- Accuracy: ±1.0% or ±1.5% of reading

- Repeatability: ±0.2%

- Nominal diameter: DN15–DN300

- Medium: Steam, gas, liquids

- Outputs: Pulse, 4–20 mA, RS-485, etc

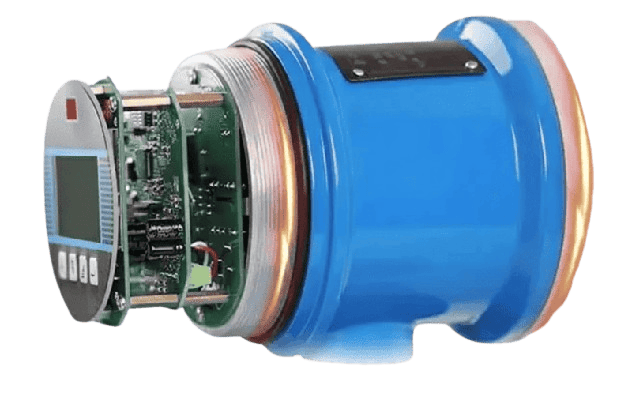

Inline Vortex Flowmeter

Compact inline construction for stable measurement accuracy in smaller pipelines.

- Accuracy: ±1.0–1.5%

- Repeatability: ±0.2%

- Nominal diameter: DN15–DN3000

- Medium temp: −40 °C to +280 °C

- Outputs: Pulse, 4–20 mA, etc

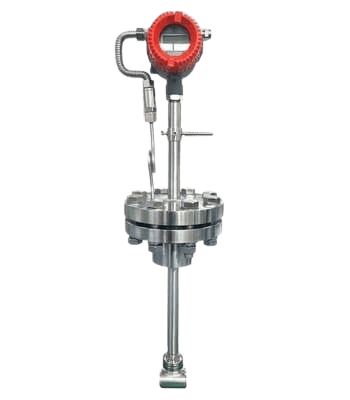

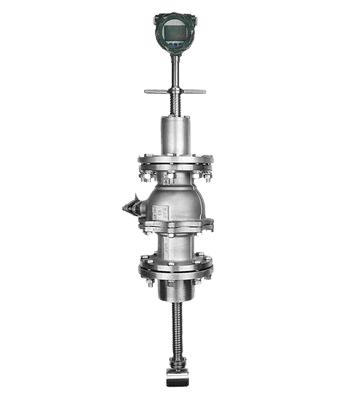

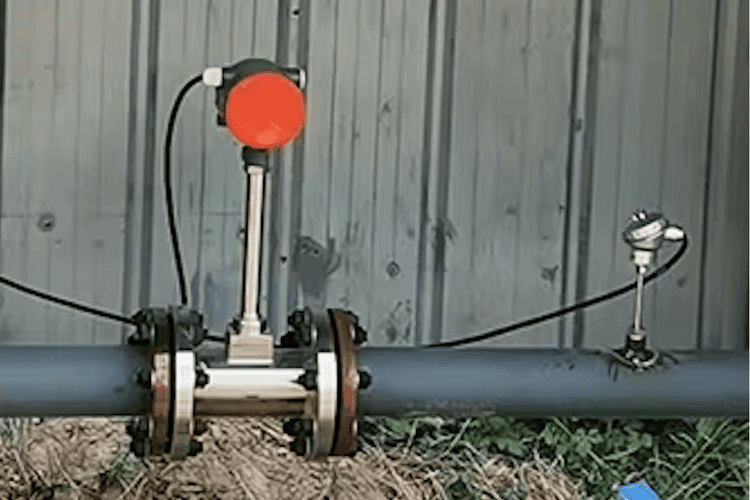

Insertion Vortex Flowmeter

Flexible, cost-effective metering for large pipelines and retrofits.

- Accuracy: ±1.5% of reading

- Repeatability: Better than 0.5%

- Nominal diameter: DN200–DN2000

- Range ratio: 1:6 to 1:30

- Protection class: IP65/IP67/IP68

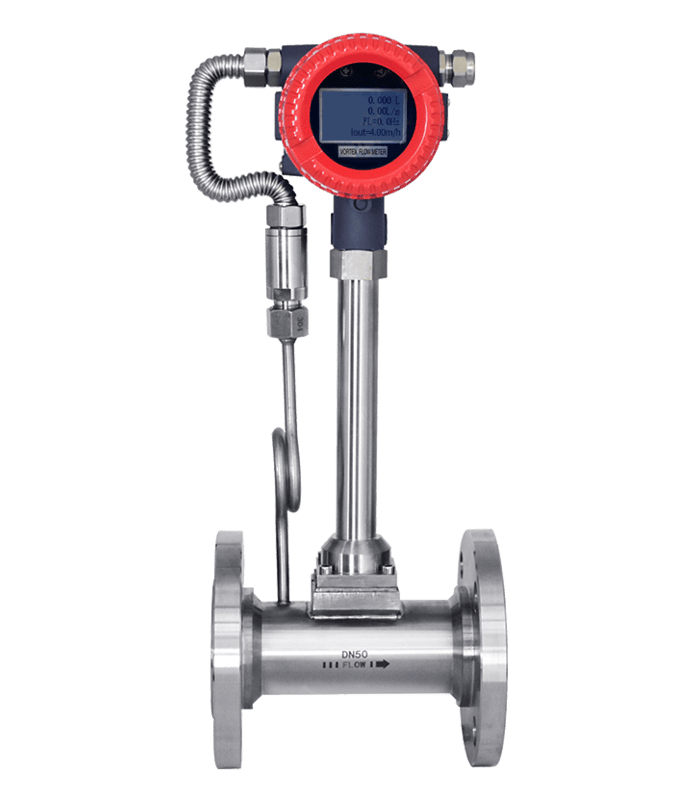

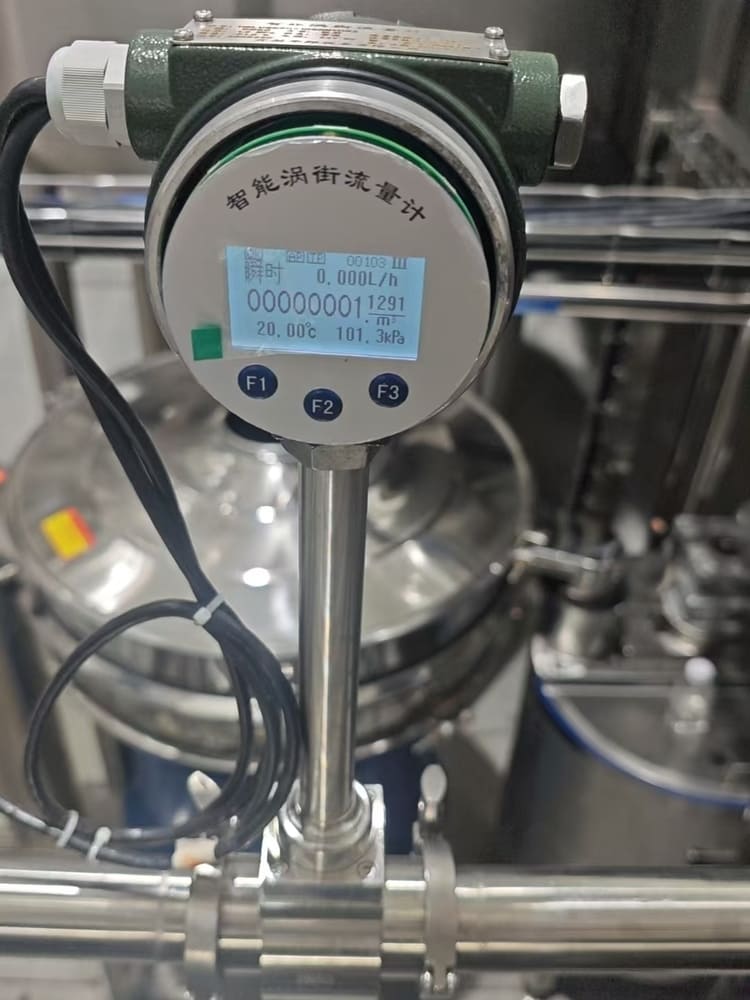

Temperature & Pressure Compensation Vortex Flowmeter

Optimized for accurate mass- or standard-volume measurement of steam and gases.

- Accuracy: ±1.0%/liquid, ±1.5%/gas or steam

- Repeatability: ±0.2%

- Nominal diameter: DN15–DN1000

- Medium: Steam, natural gas, compressed air

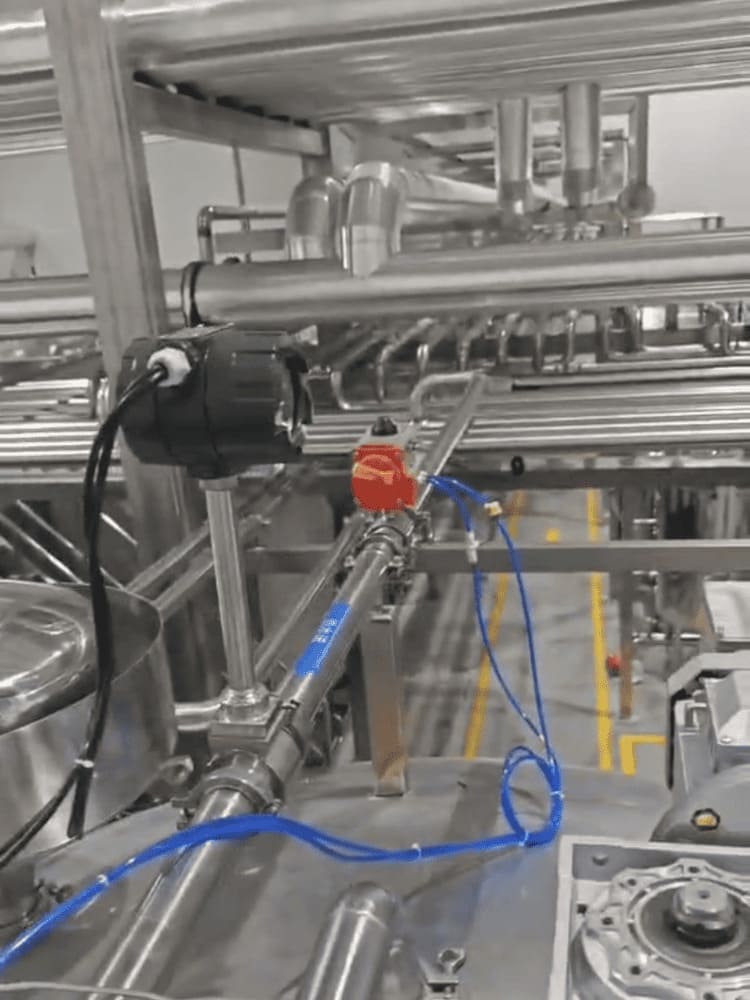

Ball Valve Vortex Flowmeter

Built-in isolation valve enables installation and maintenance without pipeline shutdown.

- Accuracy: ±1.0–1.5%

- Repeatability: up to ±0.2%

- Range Ratio: 1 : 10 – 1 : 20

- Process Temperature:−40 °C ~ +350 °C

- Ingress Protection: IP65/IP68

Tri-Clamp Vortex Flowmeter

Sanitary design for food, beverage, and pharmaceutical utility systems.

- Accuracy: up to ±1.0%

- Repeatability: ±0.2%

- Nominal diameter: DN15–DN500

- Medium: Clean liquids & gases

- Process Pressure: Up to 4.0 MPa

Main performance features

Design features that deliver measurable performance in real industrial environments.

Multi-Disciplinary Engineering Integration

Precision design supporting stable, repeatable flow signals.

Our vortex flow meter design is rooted in the engineering methodologies of Japan’s JIS Z8766 standard and enhanced through proprietary structural and signal-processing advancements. Each design decision—from the geometry of the vortex generator to the one-piece casting strategy—aims to ensure stable vortex formation, improved anti-interference performance, and long-term measurement repeatability in real industrial environments.

Get an instant quoteManufacturing & Quality Control

Built for Repeatable Accuracy in Demanding Environments

Our vortex flowmeters are built using robust manufacturing principles focused on eliminating variability. After precision fabrication, each unit undergoes flow curve validation, electrical noise testing, and environmental simulation. These procedures verify that the meter maintains stable output characteristics and supports reliable operation in facilities where temperature fluctuation, vibration, and load cycles are common.

Get Started with a Free Consultation!

Operational Cost Efficiency

Engineered to reduce operational overhead without compromising performance.

Stable sensing performance and a no-moving-parts structure reduce the long-term operational burden typically associated with flow measurement. By minimizing wear, service frequency, and calibration interruptions, the meter maintains predictable performance over extended operating cycles. This supports tighter utility management, reduces maintenance labor, and improves lifecycle cost efficiency across steam, gas, and clean-liquid applications.

Verified Performance, Certified Quality

Certified to the World’s Most Demanding Industrial Standards

Our flowmeters undergo comprehensive verification under recognized global standards. With SIL-3 safety, CE conformity, and explosion-proof certification, each unit delivers dependable performance and lasting operational integrity in demanding process conditions.

Over 168K Flowmeters Installed

Application Stories

From extreme temperatures to corrosive environments, our well-made vortex flowmeters can meet your quest for unparalleled accuracy and reliability!

Not sure which model fits your system? Talk to an Engineer for expert guidance.

Whether you require specialized materials for aggressive fluids, non-standard pipe sizes, or integration with existing systems, our experienced engineering team ensures optimal performance of the precision flow meter for your unique application.

Contact Us for Tailored Solutions